This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Introducing PowerTube, by TE Connectivity.

Built to tackle tomorrow’s connectivity challenges.

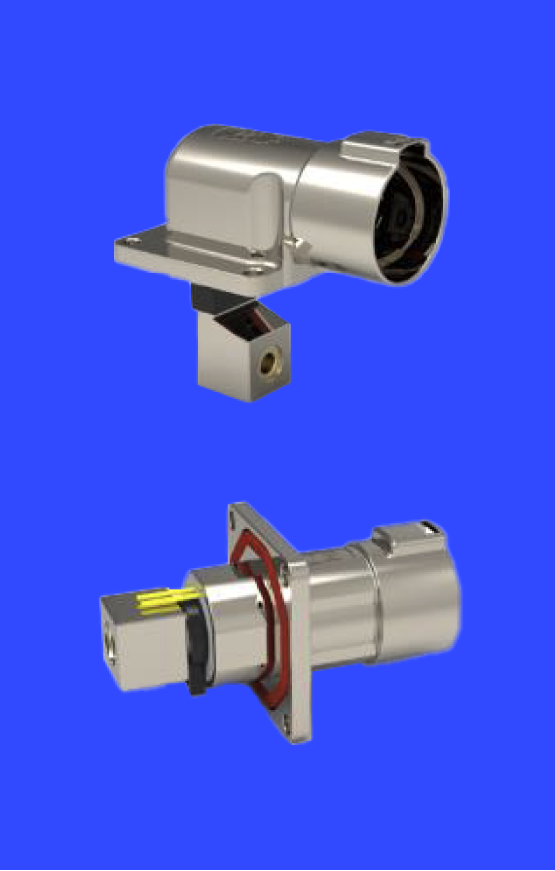

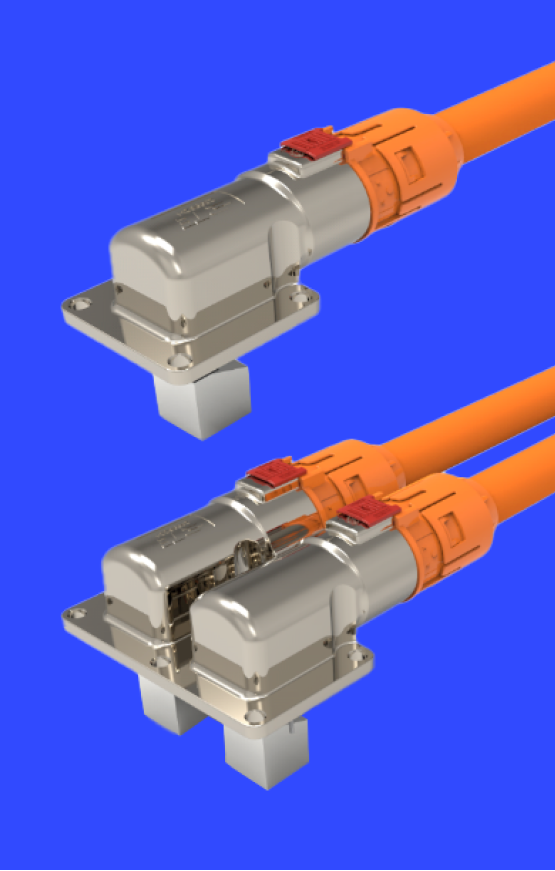

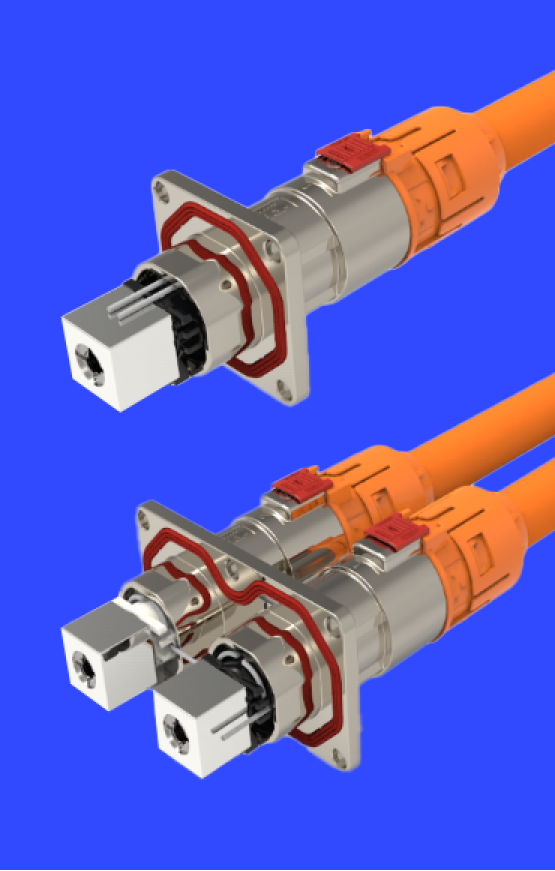

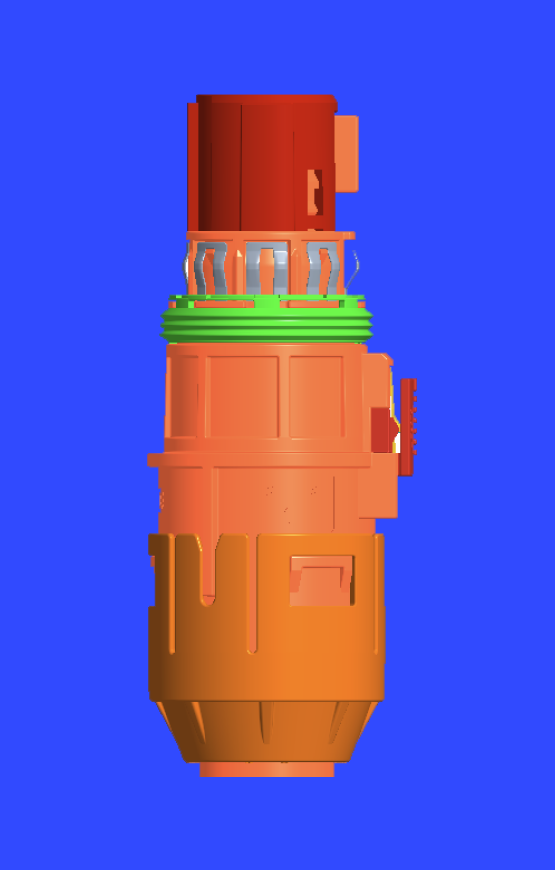

TE Connectivity is introducing a new connector system, built to solve the most pertinent problems faced by forward-thinking innovators. It handles large electrical loads, of up to 500 A continuous current and 1000 V – and it can handle multiple wire sizes (between 35 mm2 and 150 mm2).

Purpose-built for commercial and industrial electric vehicle

The PowerTube Connector Series has been devised as a solution for the harsh, intensive, high-power applications found in industrial hybrid, electric and commercial automotive. In a unique modular design, the connector series reduces overall costs – minimising your inventory, all while simplifying assembly and reducing the total number of components you need to store.